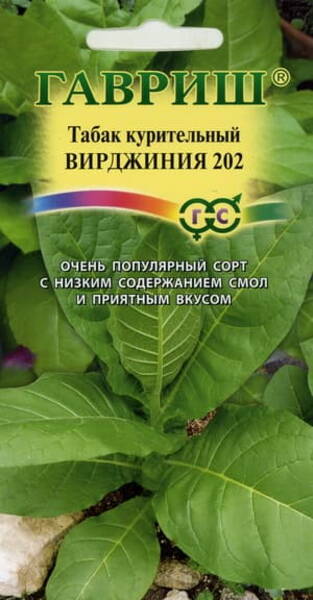

A common variety of tobacco, intended for smoking in any way, with a low tar content and a pleasant sweetish taste. Cultivated everywhere. The basis of the vast majority of pipe mixtures, one of the few types of tobacco varieties that is used in pure form.

The growing season is 111-133 days.

The plant is oval in shape, with raised large oval-elongated leaves of light green color. There are 24 leaves on the plant on average. The yield of raw materials of the first commercial grade is 97%. The average yield is 1.5 kg / m2.

Sowing for seedlings is carried out in late March-April. Before sowing, the container is filled with slightly damp soil (three parts of sandy loam turf soil and one part of well-rotted and sifted humus), the surface is compacted and leveled. The seeds are evenly distributed over the surface, lightly pressed into the substrate, moistened with a spray bottle and covered with film. The crops are placed in a bright, warm place, watered through a tray, and aired every day (the film is lifted for 30 minutes).

Young plants are planted in open ground in mid- to late May at a distance of 50-70 cm. From mid-July, the collection and drying of tobacco begins.

Tobacco is fermented before use.

* Tobacco bushes of varieties intended for covering cigars are grown in the shade - the absence of sun makes their leaves especially thin and tender. The entire plantation is covered with a special fabric - 10-20 days after planting the seedlings in the ground. A wire mesh is stretched under the fabric - the plants are tied to it.

The tobacco bushes, the leaves of which will be used for the filling and ligature, are grown in the open air. After the tobacco bush has grown to the desired size, the plantation workers pinch off the top bud to stop the growth of the plant and concentrate all the nutrients and force the development of the leaves - to be suitable for cigar production, they must be as large and juicy as possible.

After the bud is pinched off, the shoots begin to grow faster, which are just trying to intercept the flow of nutrients coming from the roots from the leaves - to prevent this from happening, the tobacco grower must visit each plant several times in the time remaining before harvesting and remove them. Like the top bud and shoots, the inflorescences are also removed. Inflorescences are left only on special plants intended for the production of seeds for the next season. Such bushes grow separately from all the others - in laboratories, in sterile conditions, under the special supervision of specialists. The seeds obtained from such bushes make up the gold reserve of Cuba - they are stored in a special warehouse and only before the beginning of the season are they given to selected tobacco growers. The harvest begins approximately 40 days after planting the seedlings and takes place in several stages.

The height of a bush grown in the sun is about 170 centimeters, on it 14 or 16 leaves are arranged in pairs. The height of a bush grown in the shade can reach 280 centimeters (the sun-deprived plant strives for it), and the number of leaves is 20 pieces.

First, the largest lower leaves are plucked. The bush with torn off lower leaves continues to grow for a few more days so that the remaining leaves have time to develop. The middle leaves are removed from the bush, a few more days pass, and those that grow even higher are plucked - they turn out to be the most rich and juicy. The upper leaves of the bush are called "ligero", the middle ones - "seco", and the lower ones - "volado". Each of these leaves in the cigar has its own function. It takes 3-4 weeks to collect all the leaves from one plant. The entire period from planting the seeds to harvesting takes 15-17 weeks.

"The older, the better".

The improvement of tobacco over time is not a psychological effect, not an idle speculation, and not a superstition. Over time, tobacco undergoes very specific changes that improve its taste dozens of times. It is no secret that all tobaccos improve over time, but not all blends improve to the same extent. For example, highly flavored tobaccos improve imperceptibly, since the sugar in such tobaccos is brought in from outside, and did not form naturally. In such aromatics, a noticeable astringent chemical aftertaste may appear over time. Its source is food additives used to flavor and moisturize tobacco. These are safe, natural sweeteners, but they greatly degrade the complex and rich taste that gradually appears in natural tobacco. Many aromatic blends mainly consist of Black Cavendish. This variety is the result of a process in which the original tobacco (usually low-quality Virginia and Burley) is heated with steam and saturated with flavors. Low-grade raw materials are usually used, since high-quality tobacco does not improve with aromatization. Indeed, you should not add sugar to a good wine, pour ketchup on a tender fillet, or use an air freshener in the garden.

However, this does not mean that there are not high-quality aromatic blends (aromatics).

For example, the "Danish" style aromatics, to which many of the blends from Peter Stokkebye belong, use very good quality tobacco, which is only slightly sweetened. Small companies producing their own blends - those that do not produce millions of kilograms of tobacco for sale in supermarkets - strive to use better quality tobacco, even in their aromatics. Such tobaccos can improve with time, at least compared to aromatics made from inferior tobaccos with more aromatization.

English and Balkan blends - containing Turkish tobaccos (including Latakia) - also improve with age. But Latakia changes little over time, remaining relatively constant.

Tobacco variety Perique, which undergoes an intense pressing and fermentation process before being blended, behaves quite differently. If improperly aged, Perique will spoil, but if stored properly and combined with Virginia, the result is excellent. Flue cured Virginias in their various varieties benefit most noticeably from long aging, due to their high sugar content. By comparison, flue cured Virginias, Turkish, Maryland, and Burley contain 22.09%, 13.39%, 0.21%, and 0.21 percent sugar, respectively. It is interesting to note how the high sugar content of Virginias, as opposed to Burleys, manifests itself during curing. Many of the chemical processes that occur in tobacco during curing continue to occur during aging, after the tobacco blend has been composed and packaged. Of course, the mechanism is no longer exactly the same. During aging, the main role is played by microorganisms that break down sugar into a large number of flavor and aroma components. That is why tobaccos with a high sugar content are preferable for aging. In any case, aging tobaccos after production is a slow continuation of the drying process. During growth, tobacco stores a significant amount of starch in its leaves. In this way, it preserves the necessary carbohydrates.

After the death of the plant, carbohydrates in the form of starch turn into sugar. In turn, sugar breaks down, forming carbon dioxide, which escapes into the atmosphere. But the difference between Virginia and Burley tobaccos is much greater than just the genetic difference between the two plants. The main difference appears during their drying. After harvesting, Burley leaves are taken to the barn. There, the tobacco slowly "ages" (this is what the process of aging and dying is called in tobacco chemistry. It is not quite the same thing, but quite close). Over a long period of time, starch turns into sugar, and then into carbon dioxide. Therefore, the sugar content in Burley is relatively low. Flue cured tobaccos start with a noticeably high starch content and a correspondingly low sugar content. When smoked, the starch produces an unpleasant, sharp, burnt, pungent taste. The curing process changes the starch/sugar ratio in the tobacco.

In a barn where the curing takes place, the tobacco leaves turn yellow at a relatively low temperature - about 38 degrees Celsius). Most of the starch is converted to sugar at this stage. But with flue cured tobacco, instead of spreading out this yellowing process over months, as is typical with Burley, you quickly raise the temperature and dry out the tobacco. This causes fermentation to stop. Since the chemical processes are stopped, the sugars do not turn into carbon dioxide.

The idea is to preserve as much sugar as possible while keeping the respiration process - the conversion of sugar to carbon dioxide - to a minimum, using up all the available starch from which sugar is formed. When properly cured, you will have a tobacco that contains little starch and up to 25 percent sugar, which plays a major role in flavor formation. Now you can process the tobacco, blend it, and package it. It is now ready to smoke, but you will not like the taste.

Virginia blends have a sharp, astringent taste and tend to smoke hot if not aged for a while. This is why most manufacturers age their tobacco for at least six months before shipping it.

At this point, we have cured and blended tobacco that has aged for a reasonable amount of time. So why are we going to continue aging it? Tobacco is much like wine.

Both tobacco and wine are natural, organic products that contain significant amounts of tannic and other acids. The taste of wine softens and becomes more complex with age, just like the taste of tobacco. Both products undergo fermentation. According to Dr. David Deinhover of the University of North Carolina, acceptable aging times for flue-cured cigarette tobacco range from one to five years, but "pipe and cigar tobacco require considerably longer to mature."